In today’s time, it is important through manufacturing to create a product that gives customer satisfaction. The priority of a business is to create products that meet or exceed customer expectations. That is why quality inspection tools help in measuring product quality in various ways. These quality instruments are capable of measuring the exact quality of the product during the production process itself.

With the help of quality inspection tools, we have been able to identify and correct defects and deviations at the right time and deliver the product to our customers as per their expectations. Through this article, we will understand in depth about quality inspection equipment, and try to know about all the important benefits of its use in manufacturing.

What is quality inspection?

Quality inspection, also known as quality control, is the process of evaluating products or components. With its help, it is ensured whether the products produced meet the specified standards and requirements or not. It is through quality inspection that defects and deviations are identified and rectified.

Importance of quality control in manufacturing

Quality control is very important in manufacturing because, with the help of quality control, it helps in identifying and rectifying various types of minor or major defects or deviations present in the product during the production process itself. Due to this, the customer gets a better quality product, and their confidence in the business increases. It is with the help of quality control that manufacturers have been able to build their brand reputation in today’s competitive market by producing products of the highest quality. That is why quality inspection tools play an important role in quality control.

Types of Quality Inspection Tools

Quality inspection instruments are classified into traditional and advanced instruments as follows:

Manual Inspection Tools

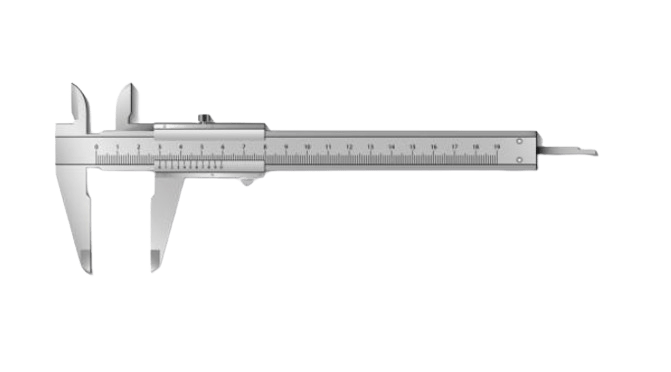

Calipers and Micrometers

Calipers and micrometers are used for precise measurements. With the help of these, the smallest dimensions of any product like length, thickness, outer diameter, inner diameter, etc. are measured in accurate values. It plays an important role in verifying the features of the product.

Go/No-Go Gauges

Go/No-Go gauges are gauges that are used to determine whether any part of a product meets or does not meet acceptable tolerances. They help indicate pass or fail criteria without the need for detailed measurements. By doing this the inspection process is streamlined.

Advanced Inspection Tools

Coordinate Measuring Machines (CMM)

CMM is used to capture three-dimensional coordinates of the complex geometry of any product. It is capable of taking highly accurate and versatile measurements of the product. This makes it ideal for inspecting complex components with the tightest of tolerances in product testing.

Optical Inspection Systems

Optical inspection systems can inspect the quality, dimensions, and defects of the product without having to get close to or touch it. Its advanced imaging technology inspects products and provides accurate resolution of large quantities of components at once, allowing for faster inspection capabilities.

Benefits of Quality Inspection Tools

Using quality inspection equipment provides a variety of benefits to the manufacturer:

Improving Product Quality

Quality inspection tools are capable of quickly detecting all the defects and deviations in any product. With this, we detect the defect at the right time and by correcting it, we improve the quality of our product. Due to this credibility is maintained between the consumer and the manufacturer.

Enhancing Productivity

Quality inspection tools significantly increase production and streamline the production process by automating inspection tasks and reducing manual intervention during the production process itself. This not only speeds up throughput but also reduces downtime associated with manual inspection.

Reducing Costs

Using quality inspection tools reduces defects during production that lead to increased rework of scrap. Because quality inspection, if not used, will result in product defects resulting in increased scrap and rework, using quality inspection tools reduces costly errors and saves extra costs for the manufacturer.

Implementing Quality Inspection Tools

To use quality inspection equipment successfully, it is necessary to have complete knowledge of it so that no error occurs during the work process. Some successful methods for this are as follows:

Training and Education

Training and education are important to have proper knowledge of quality inspection equipment. For this, the inspection equipment staff should be trained on these quality equipment by influential employees. With its help, employees will be able to utilize the full potential of the quality inspection equipment and no mistakes will be made by the equipment-related employees during production inspection.

Integration with Existing Systems

Integrating quality inspection tools with existing manufacturing systems, including ERP and MES software, facilitates process optimization and seamless data exchange. This integration helps enhance analysis, decision-making, and continuous improvement efforts.

Top 10 Quality Inspection Tools

1. Micrometer:

Micrometers are used to make precise measurements in manufacturing. With the help of this instrument, small distances or thicknesses are measured with utmost accuracy. The micrometer consists of a calibrated screw mechanism and a spindle with the help of which the screw is rotated. It can measure down to thousandths of an inch or hundredths of a millimeter.

It is used in engineering, manufacturing, and scientific research to perform precise measurements of part inspection and material thickness analysis. Micrometers are indispensable in ensuring the quality and accuracy of machined components and products.

2. Vernier Calipers:

Vernier Caliper is an instrument used in quality inspection equipment to provide an accurate measurement. This instrument is completely manual. Which is used to accurately measure the overall dimensions of any object.

Talking about its design, it has two jaws, one fixed and the other movable, and readings are written on them, with the help of which the dimensions of the product are measured. Apart from this, with the help of external diameter, length, width, and depth are measured. The least count of the vernier caliper is 0.02 mm. It is a versatile tool for accurately measuring dimensional analysis.

3. Closed-circuit television (CCTV):

Closed-circuit television (CCTV) has emerged as a reliable supporting quality inspection tool in today’s fast-paced manufacturing scenario. It plays an important role in maintaining product standards. These are used to monitor the process in production so that there are no defects or deviations in the quality standards.

With the help of closed-circuit television (CCTV), faults or deviations can be detected quickly. For this, CCTV with high-definition cameras and advanced analysis is used. Which provides us with visibility and accuracy. The use of CCTV has significantly improved productivity and efficiency.

4. Barcode:

Barcodes play an important role in manufacturing. With their help, important information is encoded in patterns of lines. Each barcode contains important details of the product. This leaves no possibility of any standard error.

Inspectors measure the manufacturing date and batch number in a specific line pattern during the inspection process itself. Barcodes are scanned with the help of a scanner, with the help of which we get various information about the product like manufacturing date, batch number, expiry date, production date, etc. After scanning the barcode, the complete information of the barcode is visible in the connected device(monitor).

5. Measuring tape:

Measuring tape as a quality inspection tool is used in manufacturing to make accurate measurements of a product. With its help, accurate dimensional information about the product is obtained. A measuring tape is used to measure various dimensions of a product. They are used in all fields.

It is only because of the quality of the measuring tape that we know the length, thickness, and width of any object. Which helps a lot in producing better products in the business. These tapes are capable of doing all types of measurements like millimeters, inches, and feet.

6. Check sheet:

Check sheet is an invaluable tool in the quality inspection process. Which helps a lot in increasing productivity and efficiency. With its help, details of productivity and efficiency data are recorded in simple words, after which this data is analyzed and results are obtained.

According to the standardization system of the inspection process, check sheets are made. In which the employee fills in various information like start time, workflow, error, production downtime, etc. With its help, systematic analysis and identification of trends or patterns becomes easier. That is, a check sheet works as a quality tool to record all the processes in manufacturing and make the production process valuable.

7. Chamfer gauges:

Chamfer gauge is a precision measuring tool used in manufacturing to measure the angle and dimension of product edges or corners. Its design usually consists of a flat reference surface and a blade. Which precisely determines the angle and width of the chamber and aligns with it.

Chamfer gauge meets all the requirements specified to provide accurate measurements. It is commonly used in manufacturing, engineering, and construction processes or industries to keep precise chamber dimensions for proper fitment and working capacity.

8. Scatter diagram:

Scatter diagrams as a quality inspection tool are an invaluable aid in increasing productivity and efficiency. These diagrams provide a visual representation of the relationship between two variables that allows identifying potential correlations, trends, and patterns within a data set.

9. Pantone Swatch:

Pantone swatches are used in various industries like fashion printing and graphic designing. It is a standardized color swatch used in all of them. These swatches provide a universal language for accurately communicating and reproducing colors. Each swatch is represented as an alphanumeric code, making it easier to colorize different mediums and materials.

Designers rely on Pantone swatches during any project, whether they’re selecting fabrics or not. It specifies the color of the ink used for printing. With Pantone swatches professionals are bringing a creative approach into their production process with confidence and accuracy. It enhances the quality to a great extent.

10. Bore Gauge:

Bore gauge serves as an important instrument in the field of quality inspection. With the help of this instrument accurate measurement of internal diameter is ensured. Which is important for assessing the conformance of any machined part of any product.

Bore gauge as a quality inspection tool guarantees strict quality standards. Helps in increasing both productivity and efficiency. With its help, stability and reliability are maintained in all lines of the production process. And consumers are assured of the delivery of top-class products. This quality inspection equipment is very useful in any production process.

Final thought:

Manufacturers use quality inspection tools to make high-quality products. The use of tools ensures the accuracy and efficiency of the products. Businesses increase productivity by taking advantage of advanced quality inspection tools and implementing robust quality control processes.

Using inspection tools efficiently ensures customer satisfaction. This also reduces the costs involved in the manufacturing process and gains a competitive edge in the market. Quality inspection equipment is used in everything from automotive to aerospace.

FAQs:

What are Quality Inspection Tools?

Quality inspection tools are tools that are used in manufacturing to check the quality of a product being produced. Their use helps in identifying the defects or deviations present in the products and rectifying them.

What are 3 quality inspection tools?

The three quality inspection tools are Micrometer, Caliper, and Chamber gauge. With their help, various dimensions of products are measured.

What factors should be considered when choosing quality inspection equipment?

Consider accuracy, reliability, speed, and ease of use when choosing quality inspection tools. Select equipment based on specific inspection requirements, product types, and production environments to ensure optimal performance and efficiency.

Also Read:

- Top 10 Quality Inspection Tools Every Manufacturer Needs

- Quality Inspection vs. Quality Inspection Tools

- How Quality Inspection Tools Save Your Business Money

- Cost-Benefit Analysis of Quality Inspection Tools: Maximizing ROI

Discover more from TrustiGauge

Subscribe to get the latest posts sent to your email.

1 thought on “Quality Inspection Tools: Enhancing Productivity and Efficiency”